EMC电磁兼容和可靠性分析仪器、仪表、设备综合服务供应商

芯片级、板级、系统级ESD静电抗扰和EMI电磁干扰测试方案定制商

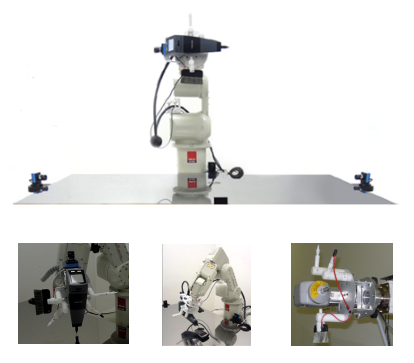

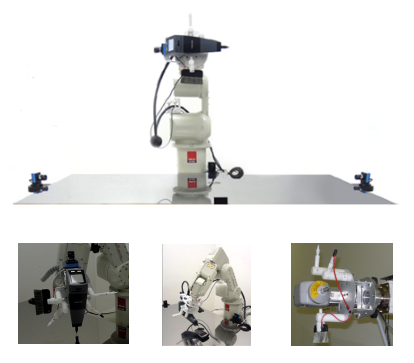

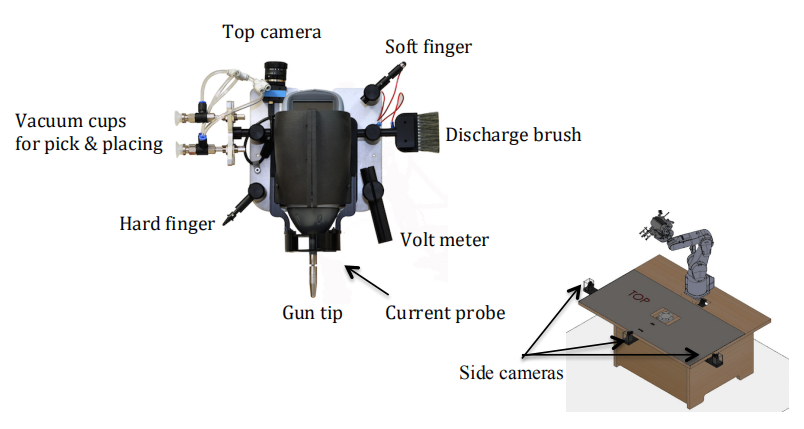

SmartZap是一款具有自动故障检测功能的全自动静电枪测试仪,其性能远优于手动静电测试。 符合IEC61000-4-2测试标准。

Robotic ESD Gun Tester SmartZap

SmartZap静电枪自动化测试系统SmartZap是一款具有自动故障检测功能的全自动静电枪测试仪,其性能远优于手动静电测试。 符合IEC61000-4-2测试标准。

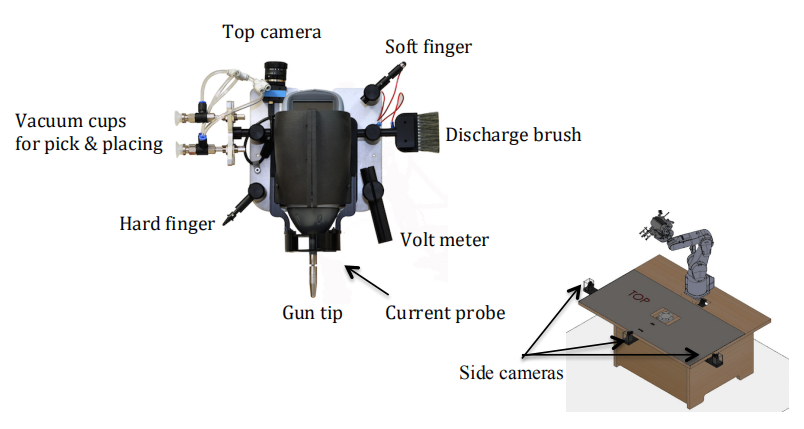

主要特点

-

支持各类型号的静电枪

- 五个侧面击打(顶部和四个侧面)

- 自动故障检测

- 挑选和放置

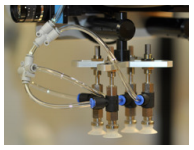

- 自动更换枪头 (接触ßà 空气)

- 连接器插头/拔出

- DUT 翻转

- 可定制的报告生成

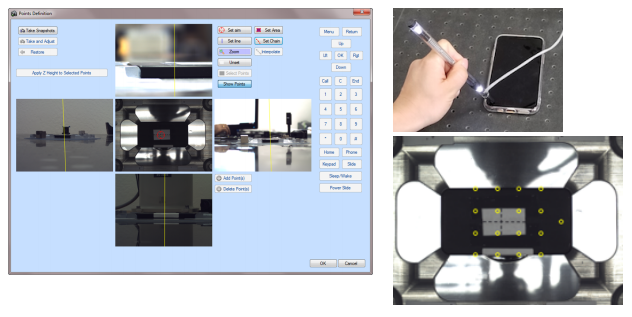

- 通过图形界面定义测试点

- 自动DUT偏移校正

-

按键和触摸屏手指

- 放电刷

- 符合IEC 61000 – 4 – 2的打击桌子

- 管脚测试

- 基于脚本的测试流程

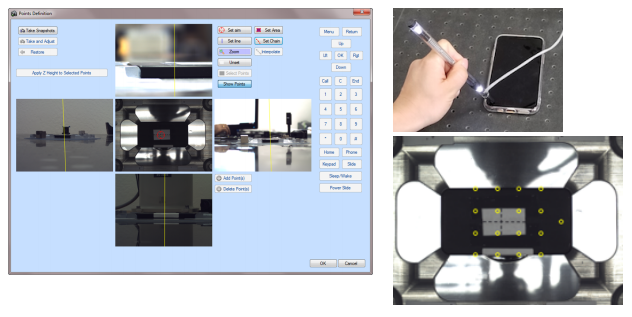

打击点 的定义

-Zap点的定义可以是(1)教学,(2)集成五个摄像头或(3)API开发的“魔术棒”。

|

|

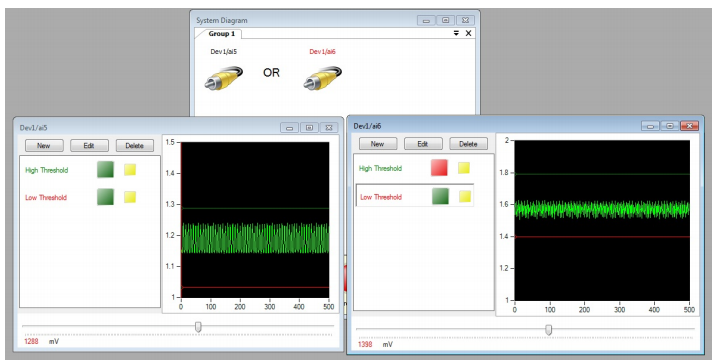

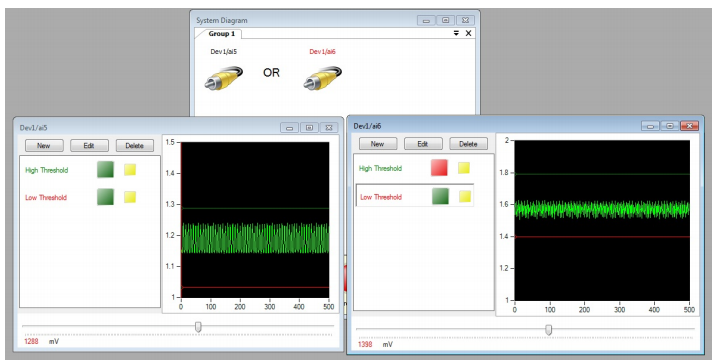

故障检测

-FD模块包括四个模拟信号和四个数字信号的监测、来自光电传感器和1KHz声音的输入、与呼叫箱、继电器和120V/5A电源的通信,用于DUT的电源循环。

-对监测信号进行布尔运算以筛选故障类型

-宏功能,用于逐步控制故障检测和功率循环程序。

自动化功能

–气动的所有自动功能,无需附加的电动附件。

-DUT取放

-枪头更换

-连接器插头/拔出

-DUT翻转

-DUT偏移校正:当DUT与原始位置略微偏离时,将自动调整定义的测试点。

报告生成

-用户可以自定义报告模板

SmartZap 规格

|

品名 |

规格 |

备注 |

| 尺寸 |

200 cm X 130 cm X 180cm |

机器手处于运送姿势 |

| 重量 |

80kg |

机械手 - 36 Kg, 桌子和配件 - 45 Kg |

|

最小测试点步进 |

500 um or better |

|

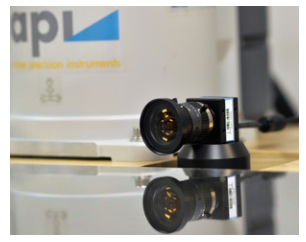

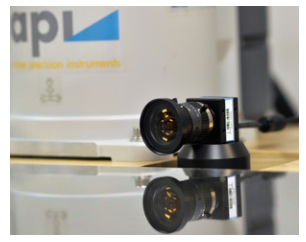

| 摄像头 |

640*480 pixels, CCD |

6摄像头- 顶部, 四周和底部 |

|

功率要求 |

< 1,500 Watt |

机械手:1150 W,220V,单相 |

机械手

| 轴数 |

6 轴 |

6自由度定位 |

|

机器手有效载荷 |

5 kg |

|

|

机械手尺寸 |

1300mm(高 ) 1200mm(宽) |

所有手臂均以90o度完全伸展 |

| 重复性 |

50 um |

|

|

轴角度 速度 |

150~500o/sec |

各轴不同 |

|

驱动方式 |

50~400 Watt |

腕轴最大值

|

|

位移 |

分辨率- < 50 um |

枪尖和枪口之间的间隙测量

|

|

操作软件 |

MFC based VC++ |

接近实时监控 |

| 机械手控制器 |

基于DSP的运动控制器:12轴,48个I/O点,16个ADC通道 |

快速信号传输与采集 |

SmartZap - 选件

PM气动回路模块

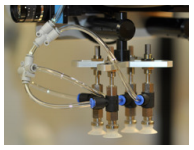

·提供正压或负压(真空)逻辑

·为了最大程度地减少SmartZap周围的电子设备,通过气动回路执行逻辑控制

·选件V1〜V4需要此气动回路模块

V1尖端变化(1,2)

·气动回路辅助自动触点/气动换尖站

·可能不适用于所有型号的枪。联系我们

|

V2挑放(2)

·适用于平板电脑,如手机或平板电脑

|

V3 DUT翻转(2)

·适用于平板电脑,如手机或平板电脑

V4

电离器(2,3)

·气动电路控制电离激活/去激活以去除残余电荷

CT顶部摄像机

·除了从顶部拍摄照片外,顶部摄像机还启用“测试点分配编辑器”

·(X,Y)测试点的坐标可以由图形用户界面在图片上定义

·可以使用图形用户界面定义分散的测试点、直线上的点和/或X-Y数组格式的点

·从N,E,W和South的四个侧面拍摄DUT图片

·在任何DUT侧面图片上启用测试点的Z高度分配

·与选项V1结合,可以使用GUI定义测试点的(x,y,z)坐标

WM放电

波形测量(3)

·每一次放电的枪放电波形都可以由电流探头和示波器捕捉并以文本文件格式保存

·此选项包括一个电流探针、安装支架和一个示波器型号的驱动器

VM 电压表(3)

·无触点现场仪表集成

·可根据现场测量结果激活电离器

FH硬指·弹簧加载的delrin指,用于开关操作的DUT按钮

FS软手指

·用于触摸屏操作

DB放电刷

·导电刷

·用户可定义刷的动作

QD 快速断开

·特殊设计的枪械安装支架,方便快捷地安装和拆卸枪械

·提供用户选项,以选择仅使用一支枪进行自动或手动测试

·特殊设计的枪械安装支架,方便快捷地安装和拆卸枪械

·提供用户选项,以选择仅使用一支枪进行自动或手动测试

FD自动故障检测模块

·静止图像比较

·1kHz声音中断检测

·基于API FD模块的自动故障检测(监视数字,模拟信号,光电传感器输出)

·可以进行定制,但需要支付额外费用(集成呼叫盒或DUT控制器)

PT针测试

·汽车行业专用模块,可在水平或垂直方向上进行引脚测试

安全围栏

·带安全互锁和系统状态LED

·提供各种型号和尺寸。 联系我们

笔记:

(1) 可提供改进后的炮尖波形

(2) 选项V1、V2、V3或V4需要选项“VLM”,即气动回路模块

(3) 电离器、场计或示波器由用户提供

机器手选项

·可以集成任何大小的机器人手臂。

·标准臂长为645毫米。 臂长较长的机器人集成可能需要支付额外费用(主要是机器人成本差异)。

·最常见的不同臂长是545 mm和900 mm。 可以提供3D机器人覆盖范围的仿真结果,以帮助选择手臂长度

系统级ESD测试

系统级ESD测试的方法在IEC 61000-4-2标准中已标准化。 该标准设置了最低要求,并提供了有关测试设置的信息。 标准制定机构考虑了手动测试,但不排除机器人测试。 考虑到手动测试,已经设置了许多最小参数,从而导致了可重复性问题。

三个主要参数是:

·放电次数

每个测试点的放电次数设置为10。这是一个非常低的数字来捕捉敏感窗口。在很短的一段时间内,受验设备对静电放电更加敏感。这些窗口通常是由软件活动引起的。Bob Renninger和Habiger研究了机会窗口的影响和达到统计稳定结果所需的脉冲数,并将其应用到ANSI ESD中C63.16节标准(草案)。简而言之,分析表明:人们必须运用更多的脉冲来捕捉机会之窗。准确的数字取决于灵敏度随时间的分布。制定标准的机构,明知故犯地忽略了这些事实,因为成员们不想强迫每个实验室执行例如,每个测试点100次放电,特别是在空气放电模式下。然而,为了从大量的放电中获得统计上稳定的结果是需要的。

·接近速度、接近角

空气放电测试很大程度上取决于电弧的长度。对于相同的测试点和电压,电弧的长度可以变化很大。这些变化部分来自统计性质,但也受方法执行方式的影响。在较高的接近速度下(这是标准制定机构的意图),上升时间平均较低,峰值平均较高。该标准对预期的接近速度几乎没有深入了解。一些测试实验室甚至将带电的空气放电尖端拖过产品(与塑料表面接触)以查看是否发生放电。这是一个非常危险的做法,因为这可能导致高过电压的esd具有不真实的低上升时间。重要的是控制接近的方式(直达预期放电点)和控制静电放电发生器的角度,因为这将影响放电电流(微弱),但对产品的耦合强烈。

如果发生上升速度快得多的放电,操作员无法在手动系统级测试中了解。

·电压增量

电压通常以大增量设置,如2、4、8千伏,只报告通过或失败。从对比试验室的角度来看,了解故障水平是很重要的。例如,如果一个实验室通过了8千伏(包括8千伏),但产品在8.001号如果然后在另一个实验室重新测试并在8kV下失败,那么测试的不确定度可能只有0.001分千伏。当然,ESD测试中的实际不确定性要高得多,但是这个例子说明我们不仅需要通过/失败,而且还需要失败级别。只有当电压以相对较小的增量(可能是1000V)增加时,才能发现这种情况。标准制定机构不希望要求这样做,因为

手部操作人员承受的压力被认为过高。

·重复率

空气放电的测试通常在每秒1个脉冲时进行。理论上,如果能够(1)消除放电之间的电荷,(2)验证EUT(3)的功能,并且能够将ESD发生器移回放电位置,则测试速度会快得多。在手试中,这是很难实现的。然而,在机器人测试中,即使在空气放电测试中也可以获得更快的速度。

机械手测试

机器人ESD测试代替了人的手动操作。这有以下优点:

重复性

机器人系统能够以非常精确的方式在每次放电时接近EUT。诸如进场速度和进场角度之类的参数得到了很好的控制。

测试深度

手工测试受到以下限制:施加的ESD数量,测试的水平和补充速率。机器人扫描不知道疲劳。可以以较小的增量将更多数量的脉冲应用于更多的测试点,以获得更好的,统计上更可靠的测试结果。机器人测试结果将涵盖其他实验室可能实现的各种可能的测试结果。

文献资料

机器人测试可以捕获每次放电的放电电流,知道是否发生了非常快速的上升时间事件并与观察到的故障相关。此外,可以在每个测试点拍摄测试照片,并验证每个放电(或没有放电)。

放电电流波形可以验证产品是否浮动,电缆是否连接或产品是否接地。

机器人测试可以成为“黄金标准”,并有助于培训操作员(例如,向他们展示进近速度的影响)或与其他实验室发生纠纷。

扩展到其他功能

机器人测试仪可以执行其他功能,例如按下旋钮以重置产品,或用于现场消光和其他抗扰度测试。

测试速度

如果将适当数量的ESD应用于产品,则机器人测试将提供较大的测试速度优势。 如果测试样本的数量大于一个,则该数量将进一步增加。

The SmartZap is a fully automated ESD gun tester with automatic failure detection capability, providing far superior performance than manual zap gun test. It is complying IEC61000-4-2 test standard.

Main Features

-

Support of any ESD gun model

- Five sides zap (top and four sides)

- Automated failure detection

- Pick and placing

- Automatic gun tip change (contact ßà air)

- Connector plug/unplug

- DUT flipping

- Customizable report generation

- Test point definition by graphic interface

- Automatic DUT offset correction

-

Key press and touch screen fingers

- Discharge brush

- IEC 61000 – 4 – 2 compliant zap table

- Pin test

- Script based test flow

Zap point definition

- Zap point are defined either by (1) teaching, (2) integrated five cameras or (3) API developed "magic wand".

|

|

Failure detection

- FD module includes monitoring of four analog and four digital signals, input from photo sensors and 1KHz sound, communication with a call box, a relay and a 120V/5Amp power supply for DUT power cycle.

- Boolean operation of monitoring signals to sort out failure type

- Macro function for step by step control of failure detection and power cycle procedures.

Automated features

– All automated functions done by pneumatic without additional electrically powered accessories.

- DUT pick-and-placing

- Gun tip change

- Connector plug/unplug

- DUT flipping

- DUT offset correction: automatic adjustment of defined test points when the DUT is placed slight off from the original position.

Report generation

- User can customize report templates

SmartZap Specifications

|

Items |

Spec. |

Comments |

|

Dimension |

200 cm X 130 cm X 180cm |

Robot in shipping posture |

|

Weight |

80kg |

Robot - 36 Kg, Table and accessories - 45 Kg |

|

Min. test point step |

500 um or better |

|

|

camera |

640*480 pixels, CCD |

Six cameras - Top, NEWS and bottom |

|

Power requirement |

< 1,500 Watt |

Robot: 1150 W, 220V, single phase ESD simulator, computer: < 500 W |

Robot

|

No. of axes |

6 axes |

6 DOF positioning - enables 3D zapping capability |

|

Robot pay load |

5 kg |

|

|

Dimension of robot |

1300mm(height) 1200mm(width) |

All arm fully stretched out with 90o degrees from J1 |

|

Repeatability |

50 um |

|

|

Axis angular velocity |

150~500o/sec |

Varies at each axis |

|

Driving method |

50~400 Watt |

Wrist axis maximum, Hand axis minimum |

|

Displacement |

Resolution- < 50 um |

Gap measurement between Gun tip and injection point |

|

Operation software |

MFC based VC++ |

Close to real time monitoring and control |

|

Robot controller |

DSP based Motion controller: 12 axis, and 48 I/O points, 16 ADC channel |

Fast signal transfer and acquisition |

SmartZap - Options

PM Pneumatic circuit module

· Provides positive or negative pressure (vacuum) logic

· In order to minimize electronics around SmartZap, logic control is performed by a pneumatic circuit

· Options V1 ~ V4 require this pneumatic circuit module

V1 Tip change (1, 2) · Pneumatic circuit assisted automated contact/air tip change and tip

change station

· May not be available for all gun models. Contact API

|

V2 Pick & placing (2) · Applicable to flat DUT's, such as, cell phones or tablet PC's

|

V3 DUT flipping (2) · Applicable to flat DUT's, such as, cell phones or tablet PC's

|

V4 |

Ionizer (2, 3) |

· Pneumatic circuit controlled ionized activation / deactivation to |

|

|

|

remove residual charges |

|

CT |

Top camera |

· Top camera enables "Test point assignment editor" in addition to DUT picture taking from top side |

|

|

|

· (X, Y) coordinates of test points can be defined by GUI over the picture |

|

|

|

· Scattered test points, points on a lines, and / or points in X-Y array format can be defined using the GUI |

|

CS |

Side cameras |

· DUT picture taking from four sides, N, E, W and South · Enables z-height assignment of test points on any DUT side picture |

|

|

|

· Combined with option V1, (x, y, z) coordinates of test points can be defined using a GUI |

WM Discharge

waveform measurement (3)

· Gun discharge waveforms of every discharge can be captured by a current probe and an oscilloscope and saved in a text file format

· A current probe, mounting bracket and a driver for one oscilloscope model is included in this option

VM Voltmeter (3) · Contact-less field meter integration

· Ionizer can be activated per the field measurement results

|

FS

DB |

Soft finger

Discharge brush |

· For touch screen operation

· Conductive brush |

|

|

|

· Various movement of brushing action can be user defined |

QD Quick disconnect · Special designed gun mounting bracket to attach and detach the

gun quick and easy

· Provides the user options to choose automatic or manual test with only one gun

FD Automatic failure detection module

· Still image comparison

· 1kHz sound interruption detection

· API FD Module based automatic failure detection (monitoring of digital, analog signals, photo-sensor output)

· Customization possible at additional cost (integration of a call box or DUT controller)

|

PT |

Pin test |

· Automotive industry specific module that enables pin test in horizontal or vertical direction |

|

|

Safety fence |

· With safety inter-lock and system status LED · Various models and sizes are available. Contact API |

Notes:

(1) Waveforms from modified gun tip can be provided

(2) Options V1, V2, V3 or V4 requires Option "VLM", the pneumatic circuit module

(3) The ionizer, field meter or oscilloscope is provided by customers

Robot options

· Any arm size of robot can be integrated.

· Standard arm length is 645 mm. Additional charge may apply for longer arm length robot integration (mainly robot cost difference).

· Most common different arm lengths are 545 mm and 900 mm. Simulation results of robot coverage in 3D can be provided to assist arm length selection

System level ESD test

The methodology for system level ESD testing is standardized in the IEC 61000-4-2 standard. This standard sets minimal requirements and gives information on the test setup. The standard setting body had hand testing in mind, but did not exclude robotic testing. As hand testing was in mind many minimal parameters have been set such that repeatability problems result.

Three main parameters are:

· Number of discharges

The number of discharges per test point is set to 10. This is a very low number to capture windows of sensitivity. There are brief periods of time in which an EUT is much more sensitive to ESD. Those windows are usually caused by software activity. The influenced windows of opportunity and the required number of pulses to achieve a statistically stable result has been investigated by Bob Renninger and Habiger and found its way into an ANSI ESD C63.16 standard (draft). In brief the analysis says: one has to apply a much greater number of pulses to capture windows of opportunity. The exact number depends on the distribution of the sensitivity over time. The standard setting bodies, knowingly had to ignore these facts, as the members did not want to force every test lab to perform e.g., 100 discharges at each test point due to strain placed on the operator, especially in air discharge mode. However, for achieving a statistically stable result from a larger number of discharges is needed.

· Approach speed, angle of approach

Air discharge testing depends strongly on the length of the arc. The length of the arc can vary, for the same test point and voltage strongly. Those variations are partially from statistical nature, but also influenced by the way the approach is performed. At higher approach speeds (this is the intention of the standard setting body) the rise time will be on average lower and the peak values will be on average higher. The standard provides little insight into the expected speed of approach. Some test labs even drag the charged air discharge tip across the product (being in contact with the plastic surface) to see if a discharge occurs. This is a very risky practice, as this can lead to highly over-voltage ESDs having unrealistically low rise times. It is important to control the way of approach (straight to the point of expected discharge) and to control the angle the ESD generator is held, as this will influence the discharge current (weakly) but the coupling to the product strongly.

If discharges that have much faster rise occur, there is no way for the operator to know in manual system level testing.

· Voltage increments

The voltage is often set in large increments, like 2, 4, 8 kV and only pass or fail is reported. From a point of view of comparing test labs, it is important to know the failure level. For example, if one lab passes up to and including 8kV but the product would fail at 8.001 kV and if then is re-tested in another lab and fails at 8kV, then the uncertainty of the testing might only be 0.001 kV. Of course, the real uncertainties in ESD testing are much higher, but the example illustrates that we not only need a pass/fail but we need a failure level. This can only be found if voltages are increased in relatively small increments, maybe 1000V. The standard setting body did not want to require this as the

strain placed on hand operators was considered to be too high.

· Repetition rate

The testing for air discharge is usually done at 1 pulse a second. In theory one could test much faster, if one can (1) Remove the charge between discharges, (2) verify the function of the EUT (3) and one is able to move the ESD generator back to the discharge position. In a hand test this is difficult to achieve. However, in a robotic testing a faster rate can be achieved even in air discharge testing.

Robotic testing

Robotic ESD testing substitutes the hand operation by a robot. This has the following set of advantages:

Repeatability

The robotic system is able to approach the EUT at every discharge in a very precise way. Parameters, such as approach speed and angle of approach, are well controlled.

Test depth

Hand testing is limited in the number of ESDs applied, the levels tested at and the repletion rate. Robotic scanning does not know fatigue. One can apply a much greater number of pulses, to many more test points at much smaller increments to achieve a better, statistically more reliable test result. Robotic test results will cover a wide range of possible test results that might be achieved in other labs.

Documentation

The robotic testing can capture the discharge current for each discharge, knowing if a very fast rise time event occurred and correlated to an observed failure. Further, photos of the testing can be taken at each test point and each discharge (or the lack of discharge) is verified.

The discharge current waveforms will allow to verify if e.g., the product is floating, if cable are attached or if the product is grounded.

A robotic test can be the “golden standard” and help in training of operators (e.g., show them the effect of speed of approach) or in disputes with other laboratories.

Extending to other functions

A robotic tester can perform other functions, like pressing knobs to reset a product, or be used for field matting and other immunity testing.

Test speed

If a suitable number of ESDs is applied to a product then robotic testing will offer a large test speed advantage. This will grow further if the number of test samples is larger than one.

某某婚礼策划

在线QQ:12345678

在线QQ: 12345678

中国某某某有限公司版权所有 沪ICP备12345X78号

COPYRIGHT 2008-2014 WWW.XXXXXX.COM.CN ALL RIGHTS RESERVED

上海市XXXX房产有限公司 沪ICP备020XXXX号 版权所有

Copyright 2016 Global Electronic AG

TeL:0731-85782021 E-mail:Billion.xiao@glb-et.com

湖南格雷柏电子科技有限公司 版权所有

上海市·某某某区·某某某路·某某某大厦·某某层

COPYRIGHT 2008-2014 WWW.XXXXXX.COM.CN ALL RIGHTS RESERVED

上海市XXXX房产有限公司 沪ICP备020XXXX号 版权所有